Chances are, you've experimented with magnets at some point in your life—perhaps as a child or even as an adult. You've probably stuck them to various surfaces to see what materials succeed and fall short when exposed to the mighty magnetic force.

Many people assume that all metals are naturally magnetic, but this isn't the case. While all magnetic materials are metal, not all metals are magnetic. Do magnets stick to aluminum? What about other materials? Below, you can learn about different magnetic and nonmagnetic surfaces and what gives them these properties.

How Does Magnetism Work?

Before we dive into different magnetic and nonmagnetic materials, it helps to understand how magnetic attraction works. Magnetism comes from the

motion of electric charges. Every material is made up of atoms — tiny particles that contain electrons. Electrons spin around the atom's nucleus, producing an electric current.

Magnets contain north and south poles. You've probably heard the saying “opposites attract,” and the same concept applies here. Opposite poles attract each other, while the same poles repel one another. When you bring a magnetic material into contact with a magnet, the atoms' north poles line up in the same direction. The aligned atoms create a force that generates a magnetic field.

In materials with weak magnetism, equal numbers of electrons spin in opposite directions, canceling out their magnetism. Comparatively, in strongly magnetic materials, most of the electrons spin in the same direction.

Sometimes, an electrical current can magnetize a material. When electricity travels through a wire coil, it generates a magnetic field. As soon as the electric current is turned off, the field around the coil disappears. This process is known as electromagnetism.

Because materials interact differently with external magnetic fields, some are more magnetic than others.

Do Magnets Stick to All Metal?

No, not all metals are magnetic. To understand why this is, we can look at these two terms:

1. Paramagnetism

Paramagnetic metals can be temporarily magnetized when subjected to a magnetic field. Their magnetic properties gradually disappear when this field is removed. They cannot produce their own magnetic fields and have a weak magnetic attraction while in their natural states.

Most — but not all — of the electrons in their atoms spin in the same direction, giving the atoms some polarity. Some paramagnetic metals are aluminum, copper, gold, brass, silver, lead, tin, and platinum. However, you can add properties like steel and iron into paramagnetic metals to strengthen their magnetism.

2. Ferromagnetism

Ferromagnetic materials retain their magnetism even when the magnetic field is removed. They have inherently strong magnetic properties, maintaining long-term magnetic fields without an external force.

For example, iron is ferromagnetic, so any metals containing iron are susceptible to magnetism. Some other ferromagnetic metals are cobalt, steel, nickel, zinc, and manganese. Rare-earth metals, such as gadolinium, lodestone, and neodymium, are also ferromagnetic.

Essentially, you can think of paramagnetic metals as temporary magnets and ferromagnetic metals as permanent magnets.

Can Nonmetals Be Magnetic?

Magnets will not stick to nonmetal materials — like plastic, wood, cloth, paper, and fiberglass — which you may know from experience. That's because these materials have low permeability — magnetization generated from an applied magnetic field — and field lines can't pass through them. There is an absence of magnetic flux, the total number of magnetic field lines traveling through a closed surface.

An external field can't induce magnetism in low-permeability materials, resulting in no magnetic attraction. These low-permeability materials can also be described as diamagnetic. This means the north and south poles repel them in a magnetic field.

As mentioned earlier, it helps to remember this principle — all magnetic materials are metal, but not all metals are magnetic.

Stainless Steel and Magnetism

Stainless steel is a durable, corrosion-resistant material used in many kitchen appliances, including refrigerators, ovens, dishwashers, range hoods, and cookware. Steel is an alloy containing ferromagnetic metals, such as iron and chromium.

However, there's some ambiguity surrounding stainless steel and magnetism. Stainless steels comprise a wide range of steel alloys with different metal compositions. Some contain more iron, and others are higher in chromium.

That's why certain types of stainless steel stick seamlessly, while different kinds have a weaker magnetic attraction. For example, you might find that a magnet sticks easily to your refrigerator but not your oven.

Austenitic vs. Ferritic Stainless Steels

Austenitic stainless steels — such as grades 303, 304, 310, 316, and 321 — are high in nickel. While nickel is ferromagnetic, austenitic stainless steels are typically nonmagnetic — they contain austenite, which is a metallic, nonmagnetic iron allotrope.

While grades like 304 and 316 are high in iron, the presence of austenite renders them paramagnetic. Generally, the higher the alloy's nickel concentration, the less magnetism. Comparatively, ferritic stainless steels — such as grades 409, 430, 434, and 439 — are richer in iron and lack austenite, giving them stronger magnetic properties.

In summary, ferritic stainless steels are usually magnetic, while most austenitic stainless steels are nonmagnetic. Ultimately, the level of magnetism depends on the type of stainless steel and its alloy composition. The strength of the magnet can also play a role. For instance, an exceptionally strong magnet may successfully stick to austenitic stainless steel. Meanwhile, a weak magnet may struggle to stick to a ferritic surface.

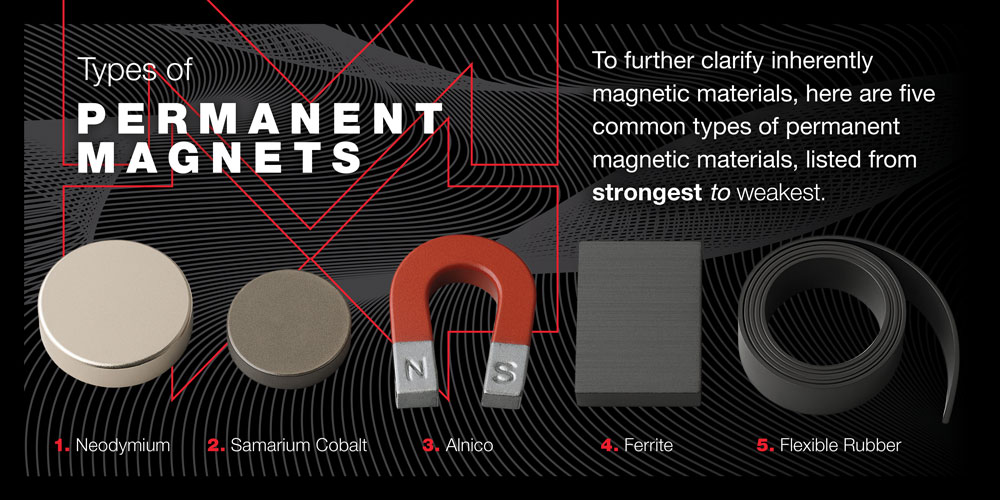

Types of Permanent Magnets

To further clarify inherently magnetic materials, below are five common types of permanent magnetic materials in order from strongest to weakest.

1. Neodymium

Neodymium magnets are alloys of the elements iron, boron, and neodymium. In some cases, they may contain traces of dysprosium and praseodymium. Neodymium and other metals create an alloy called Nd2Fe14B, the world's strongest magnetic material. Neodymium magnets are ideal for electric vehicle motors and other industrial equipment requiring optimal durability.

Neodymium magnets have tremendous strength. They can hold upward of 1,000 times their weight. They're also well-suited to applications requiring extreme demagnetization resistance. However, they have lower maximum operating temperatures than other magnets. This makes them unfit for moist environments unless equipped with a corrosion-resistant coating.

2. Samarium Cobalt

Like neodymium, samarium cobalt magnets are part of the rare earth magnetic material family. As the name suggests, they contain two elements — samarium and cobalt.

Samarium cobalt magnets aren't nearly as strong as their neodymium counterparts. However, they perform better in moist environments and high temperatures. They have superior corrosion resistance, as well. Samarium cobalt magnets

were the world's strongest magnets until neodymium magnets came along.

3. Alnico

Alnico magnets contain aluminum, cobalt, and nickel. They may not be as strong as neodymium and samarium cobalt, but they provide better stability at high operating temperatures than any other permanent magnet. However, they can be prone to demagnetization.

4. Ferrite

Ferrite magnets are made of iron. Some contain other elements like barium and strontium carbonate. While they can't rival the strength of rare earth magnets, their affordable production is a significant benefit. Due to their price, ferrite magnets are ideal for low-level applications requiring large production runs. They're also highly corrosion-resistant.

5. Flexible Rubber

Flexible rubber magnets combine magnetic particles with a polymer binder to create magnets in sheet or tape form. Though they offer less strength than solid magnets of similar sizes, they provide larger surface areas. The binder is flexible, allowing manufacturers to roll it seamlessly.

Other FAQs About Magnetic Surfaces

Now that you've learned about different magnetic and nonmagnetic materials, we'll answer some other common questions about magnets and magnetic materials below.

1. How Do You Measure a Magnet's Strength?

A magnet's maximum strength is typically determined by its pull strength, or holding power, before being separated from a steel plate. Magnetic pull strength is measured in pounds.

Typically, the entire magnetic surface is attached to a thick ground steel plate using a hook and measuring device called a dynamometer. The hook slowly pulls the magnet upward until sufficient force can break away the assembly from the plate. The dynamometer records the pounds pull.

After repeating this test numerous times, you can establish an accurate pounds pull rating for the magnet. Keep in mind that pull strength can vary with the following factors:

- Steel composition and thickness

- Steel coatings, such as grease or paint

- Uneven surface area due to rust or other contaminants

2. How Do Magnets React With Electronic Device Surfaces?

Many computers rely on magnets to store data on hard drives. Permanent magnets and electromagnets are present in various devices, like televisions, speakers, generators, and motors.

You may have heard that external magnetics and electronics don't mix. For instance, after checking into a hotel, maybe you were advised to keep the key card separated from your phone, as electronic devices can interfere with the key's magnetic strip.

Electronics store electric charges in the form of electrons. These electrons open and close current pathways using circuits. Processors store and move electrons between different transistors to run calculations. Disk-based hard drives use electronic charges on spinning magnetic disks to store and retrieve files. Electronics control the exact positioning of these charges.

Magnets exude a positive or negative magnetic charge. An electrical current amplifies an electromagnet, boosting its magnetism. When a powerful electromagnet approaches an electronic device, it can damage the transistor's or hard drive's electrons. This can interfere with the device's ability to function properly.

As a precaution, it's a good idea to keep strong electromagnetic fields away from:

- Credit cards

- Magnetic ID cards

- Videotapes

- Cassette tapes

- Televisions

- Cell phones

- Computer monitors

3. How Are Magnets Made?

Modern magnets are often manufactured through the following processes:

- Casting and sintering: Many magnets are created with sintering or casting processes. To form cast magnets, a manufacturer pours a molten metal alloy into a mold, then processes it using multiple heat treatment cycles. Sintering involves compacting and forming a solid material mass using pressure or heat. The manufacturer doesn't melt the material into a liquid.

- Injection molding: During injection molding, the material is heated and melted, then sent to a mold to cool and form the desired shape. The process resembles injecting fluids with a syringe, hence the name.

- Calendaring: Calendaring is the process of smoothening and compressing a material by passing a single continuous sheet through a series of heated rolls. These rolls are called “calendars.”

After manufacturing, most magnets require further machine processing before assembly.

4. What Are the Maximum Operating Temperatures for Different Magnets?

We mentioned that different types of permanent magnets have varying maximum operating temperatures:

- Neodymium: 284 degrees Fahrenheit

- Samarium cobalt: 572 degrees Fahrenheit

- Alnico: 1,004 degrees Fahrenheit

- Flexible rubber: 212 degrees Fahrenheit

Flexible Magnetic Products by Magnum Magnetics

At Magnum Magnetics, we specialize in custom flexible magnetic products for various applications and projects. Here are some of the many magnetic solutions we provide.

Magnetic Sheeting

Our

plain magnetic sheeting provides a streamlined option for announcements, greeting signs, prices, labels, and other key business information. Our magnetic rolls can serve a variety of purposes for your company, such as:

- Setting up marketing and advertising displays

- Welcoming customers into your business with personalized signage

- Announcing promotions, specials, and temporary business hour changes

- Helping customers and employees navigate the facility and find the correct products

Whatever your needs, we'll happily work with you to customize a product to your applications.

Adhesive Laminated Magnetic Sheeting

- Aisle labels

- Product identifications

- Greeting boards

- Announcements for seasonal deals and promotions

You can use these adhesive-backed magnets where traditional magnets won't stick, achieving a magnetic receptive surface. You can also cut the sheets into small labels for streamlined product tracking.

Our team can help you choose the ideal magnetic sheet for your applications. We will also develop a special adhesive if needed. Additionally, we can design your magnetic sheeting with vinyl laminate on one side and adhesive on the other, expanding your product options.

Our laminated adhesive magnetic sheets make it easier for employees and customers to locate inventory, all while enhancing your store's visual appeal.

Reach Out About Our Flexible Magnetic Materials Today

If you're looking for high-strength, competitively-priced magnetic products, turn to Magnum Magnetics. We manufacture our magnets from the highest quality materials right here in the United States.

We supply products for a variety of industries and applications. Whether you're searching for refrigerator magnets, photo pockets, business cards, coils, or mounting tape, we make it easy to get the solutions you need.

Additionally, we offer

magnetic product customization services. We can tailor our products to your desired width, thickness, surface, packaging configuration, and other specifications. We can also provide fast shipping since we make our products domestically.