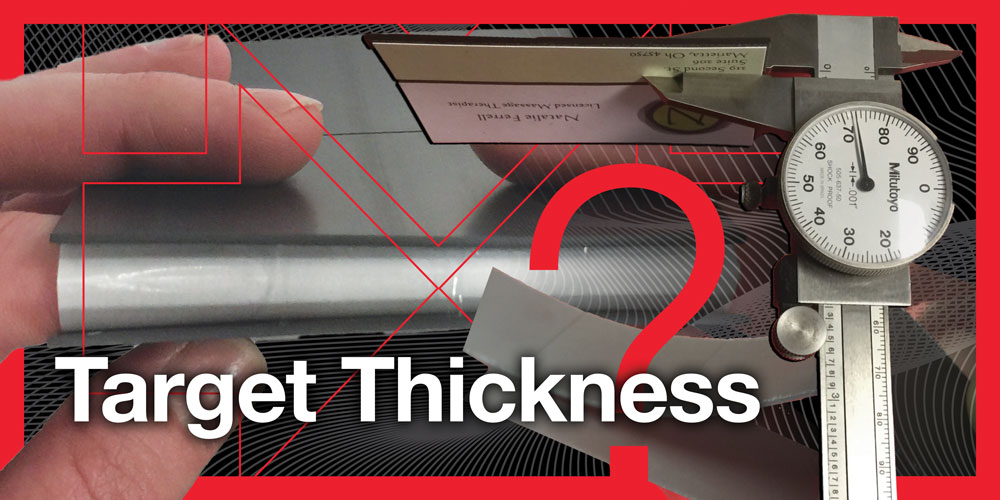

Understanding Magnet Target Thickness: Why It Matters to Get It Right

When dealing with magnetized materials, one of the most common questions is whether the thickness a customer specifies refers to the magnet alone or the entire product (magnet plus substrate). This detail may seem small, but it can be the difference between winning and losing bids, especially for high-stakes projects. In the world of magnets, precision matters—not just in terms of measurement but also in terms of understanding client needs to ensure the right solution. Here, we’ll explore why magnet target thickness is crucial, how it impacts project outcomes, and why the distinction between magnet-only thickness and total thickness is key to meeting expectations.

What Does “Magnet Target Thickness” Mean

In simple terms, magnet target thickness can refer to one of two things:

1. Magnet Thickness Alone: This is just the thickness of the magnetic material without any other layers or substrates.

2. Total Product Thickness: This includes the magnet and any additional substrates or coverings that are part of the finished product, such as a printed top layer or adhesive backing.

However, there’s a lot of ambiguity surrounding the term “target thickness.” You will likely get a split response if you ask 100 end users what they mean by a “20 mil” magnet. Half might assume that “20 mil” only refers to the magnet thickness, while the other half think it describes the combined thickness of both the magnet and its substrate. Without clarifying what the customer means by “target thickness,” you risk supplying a product that either overshoots or undershoots their needs.

Why Target Thickness Matters for Magnet Projects

Cost Implications

The magnet material itself is the primary cost driver in most magnetic products, often making up a large portion of the total cost. For example, quoting a magnet that is 20 mils thick when the client actually needed a total thickness of 20 mils (magnet plus substrate) can result in an unnecessary cost increase. In competitive bidding scenarios, this difference can be significant, possibly affecting your chances of securing the project. If a competitor quotes a magnet at 50% less thickness due to this misunderstanding, they may secure the bid with a lower price—yet with potentially insufficient pull strength for the application. When a large project is up for bid, the thickness of the magnet can heavily influence the price and the likelihood of securing the contract. Quoting a magnet with an unnecessary thickness increase could lead to a higher price, which may not be as competitive. By asking the right questions and confirming the application details, you position yourself to make an informed recommendation that aligns with the client’s actual needs. This proactive approach builds trust with clients and helps secure more successful outcomes in competitive bids. Underestimating the thickness could yield a product that doesn’t meet the client’s performance standards.

Functional Considerations: Pull Strength

Magnet thickness directly impacts pull strength, which is the force required to pull the magnet away from a ferromagnetic surface. A thicker magnet generally provides stronger pull strength, while a thinner magnet may not be able to hold as securely. If you interpret a client’s specification as “total product thickness” when they actually meant “magnet thickness alone,” the magnet you provide could lack the pull strength needed for the application, resulting in an underperforming product that may not meet the client’s expectations. This could lead to costly returns, project delays, and dissatisfied customers.

How to Clarify Magnet Target Thickness with Clients

When reviewing specifications for a magnetic product, it’s essential to clarify what “target thickness” truly means to the end user. Here are some practical ways to get a clear answer:

1. Ask About the Magnet’s Application

A straightforward question like, “What is the application of the magnet?” can be incredibly insightful. Knowing the intended use of the magnet can reveal whether the client requires a high pull strength or simply a thinner, more flexible magnet that can be layered with a printed substrate. This can guide your choice of magnet thickness to ensure the right balance of strength and functionality.

2. Confirm the Definition of Target Thickness

Directly asking whether the client’s specified thickness refers to just the magnet or the entire product can eliminate a lot of confusion. While it may seem overly simple, this question can save you—and the client—significant time and resources.

3. Suggest Expert Assistance

If there’s any uncertainty regarding the correct thickness to quote, consult the experts. Magnum Magnetics offers support for clarifying magnet specifications and can provide guidance on thickness requirements for different applications. Reaching out can prevent costly mistakes and ensure that the final product meets the intended functional requirements.

When in Doubt, Consult Magnum Magnetics

Understanding the intricacies of magnet target thickness can be challenging, especially when dealing with different industries and applications. If you find yourself unsure of how to interpret a client’s thickness specifications, don’t hesitate to seek expert advice. Magnum Magnetics has the experience and insight to help you determine the right thickness for the job, ensuring that your product performs as expected in the intended application.

In summary, whether bidding on a new project or fulfilling a custom order, the distinction between magnet-only thickness and total product thickness is vital. This single detail can impact everything from project costs to pull strength and the likelihood of winning or losing a bid. By clarifying client needs and understanding the impact of target thickness, you can make informed decisions that lead to more successful outcomes and satisfied clients.